WHAT WE DO

|

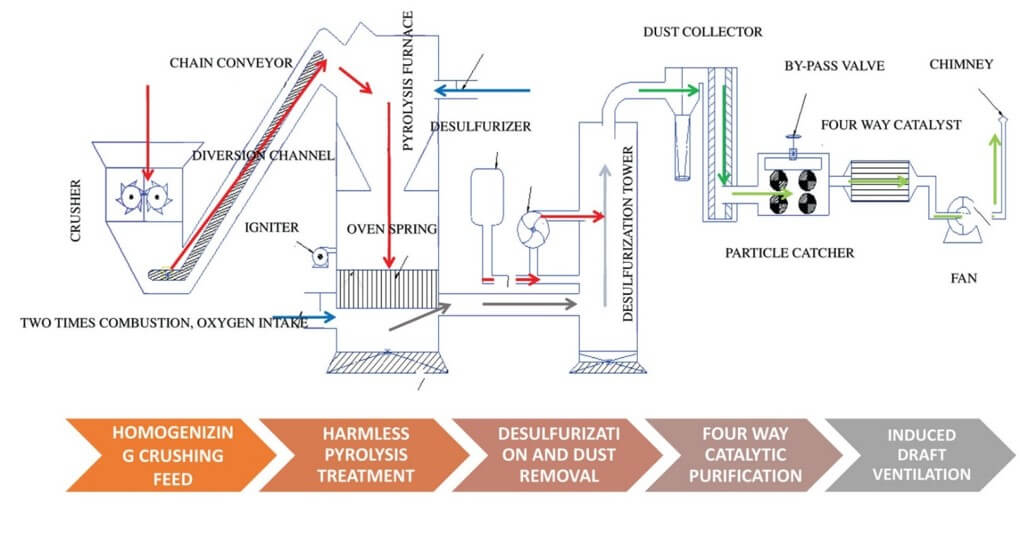

“THE PYROLYSIS PROCESS” Mobile Waste Treatment Unit MK-MWTU 6

Pyrolysis technology provides an opportunity for the conversion of municipal solid wastes, agricultural residues, scrap tires, non-recyclable plastics etc. into clean energy. |

|

|

Built with a combination of Principles and Technology

|

MK MWTU 6 – MOBILE WASTE TREATMENT UNIT- SCHEMTIC ELEVATION |

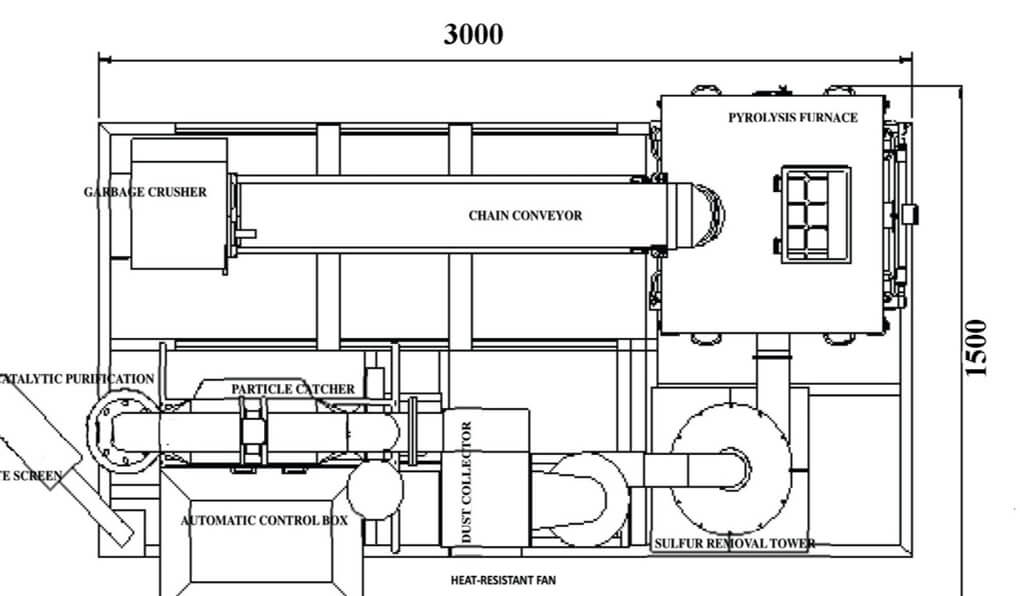

MK MWTU 6 – MOBILE WASTE TREATMENT UNIT- SCHEMTIC PLAN |

Some Key Benefits

Tested and Certified to meet the Required Standards to meet Elimination of Harmful toxins and other listed Harmful gases. There is no power source required after the initial ignition (with 5kg of Charcoal) except to run the Fan and the monitoring device. ( Every Mobile Unit comes with a Generator Set. |

| Designed and Built with Mobility in Mind. Ideal for Remote Villages and Out of Reach locations to handle waste locally.

The Mobile capable units come in 2 Tons and 5 Tons overall Dimension of the 2 Ton Unit ( MK-MWTU 6T2)3M x 1.5M x 2M. The 5 Ton Unit (MK-MWTU 6T5) measures, approximately 3.5M X 1.8 M X 2.5M. Operates at an Optimum heat of Between 300 Deg. To 450 degrees for MSW and up to 850 degrees for industrial Waste. |

|

|

|

|

|

|

ONE BIG ADVANTAGE It can be Housed within Buildings and Community Projects to handle waste locally

|

|

|

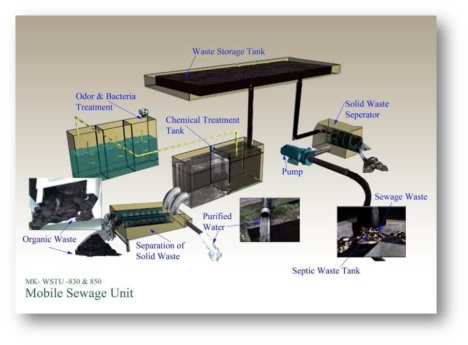

Onsite sewage treatment with the integration of advanced automation technology

Mobile treatment UNIT can process sewage at a rate of 30-50 cubic meters in a hour. Onsite dehydration processseparating solids and liquid filtering residue and with a series of treatments has achieved bio solids free from odour. |

Three stage process of Pre-Treatment Biochemical treatment (MBR film) and sludge treatment Our waste water treatment system has been perfected using “A2/O MEMBRANE BIO-REACTOR” combined with Ultra filtration membrane technology. Process uses a hollow membrane instead of the traditional activated sludge processing of secondary sedimentation tank and a third stage treatment of multimedia filtration Our Aim

|

|